TL(R) Series Horizontal FGD Pump

Basic Info

Model No.: TL(R)

Product Description

TL(R) Series Horizontal FGD Pump

• Product Introduction

TL(R) series desulfurization pump is cantilevered horizontal centrifugal slurry pump.It is double casing pump. The lining adopts replaceable hard alloy wear parts or rubber parts, which has good wear resistance, corrosion resistance and high reliability. This series pump is equipped with compact X shaped bracket for significantly saving space.It is characterized by wide flow range, high efficiency.

TL(R) series desulfurization pump is mainly used in hydro FGD system as absorber desulturizing slurry circulating pump.

• Product Feature

- The pump housing is made of replaceable hard alloy liner or rubber liner with double pump housing structure, which has good wear resistance, corrosion resistance and high reliability.

- The structure of the pump is back disassembling type for easily maintenance, it is not necessary to dismantle the inlet or outlet pipeline when maintenance is needed.

- The impeller are made from a new type of anti-abrasion and anti-corrosion material specially for FGD process, this type of material has advantages of anti-corrosion as duplex stainless steel and anti-abrasion of high chrome alloy.

- Double-Row Tapered Roller Bearing is adopted at the pump end, Cylindrical roller bearing is adopted at the drive end, and the bearings are lubricated by oil so that the condition the bearings works under is improved and the service life of the bearings is lengthened.

- Cartridge mechanical seal which is specially adopted in desulfurization process is used to make its operation much stable.

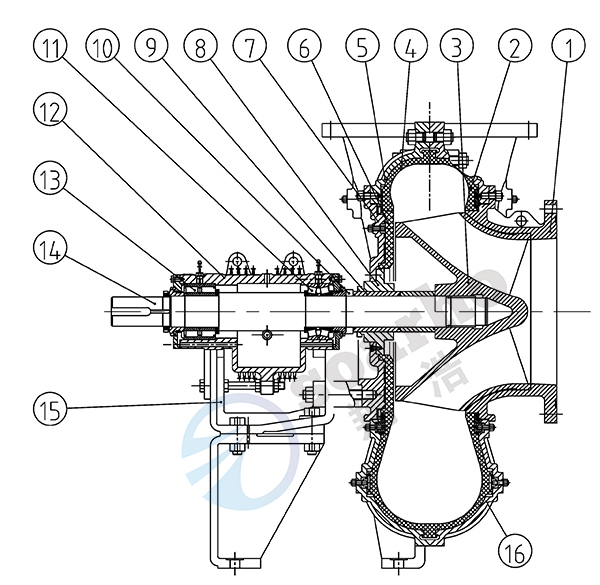

| NO. | Name | Material |

| NO. | Name | Material |

| 1 | Suction cover | A49 | 9 | Impeller release collar | Stainless steel | |

| 2 | Cover plate liner | Natural rubber+A3 | 10 | Shaft sleeve | 316 | |

| 3 | Impeller | A49 | 11 | Double-row tapered Roller Bearing |

| |

| 4 | Frame plate liner | Natural rubber+A3 | 12 | Bearing house | QT500-7 | |

| 5 | Frame plate | QT500-7 | 13 |

| ||

| 6 | Rear liner | Natural rubber+A3 | 14 | Shaft | 45 | |

| 7 | Adaptor plate | QT500-7 | 15 | Bracket | QT500-7 | |

| 8 | Mechanical seal | Hard alloy | 16 | Cover plate | QT500-7 |

Structure 1

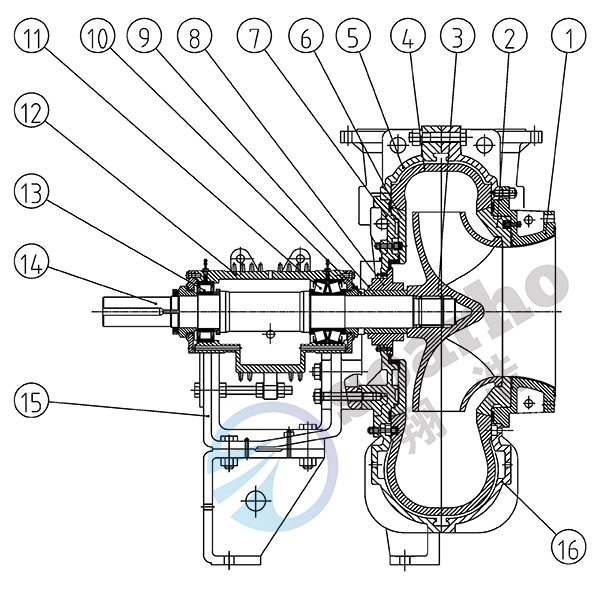

| NO. | Name | Material |

| NO. | Name | Material |

| 1 | Suction cover | QT500-7+Natural rubber | 9 | Impeller release collar | Stainless steel | |

| 2 | Throat bushing | A49 | 10 | Shaft sleeve | 316 | |

| 3 | Impeller | A49 | 11 | Double-row tapered Roller bearing |

| |

| 4 | Volute liner | A49 | 12 | Bearing house | QT500-7 | |

| 5 | Frame plate | QT500-7 | 13 | cylindrical roller bearing |

| |

| 6 | Rear liner | A49 | 14 | Shaft | 45 | |

| 7 | Adaptor plate | QT500-7 | 15 | Bracket | QT500-7 | |

| 8 | Mechanical seal | Hard alloy | 16 | Cover plate | QT500-7 |

Note:A49 material is a kind of Duplex phase anti-abrasive and anti-corrosive alloy, it widely used for FGD projects in the word.

Structure 2

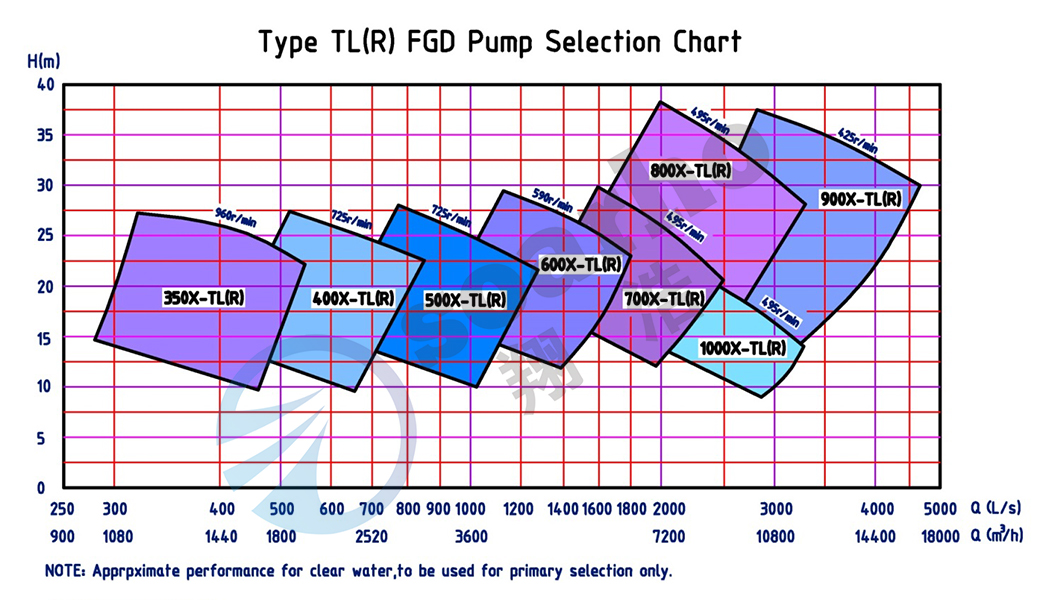

• Range of Performance

Capacity Q:80-5000m3/h

Head H:5-84m

Discharge diameter: 100-400mm

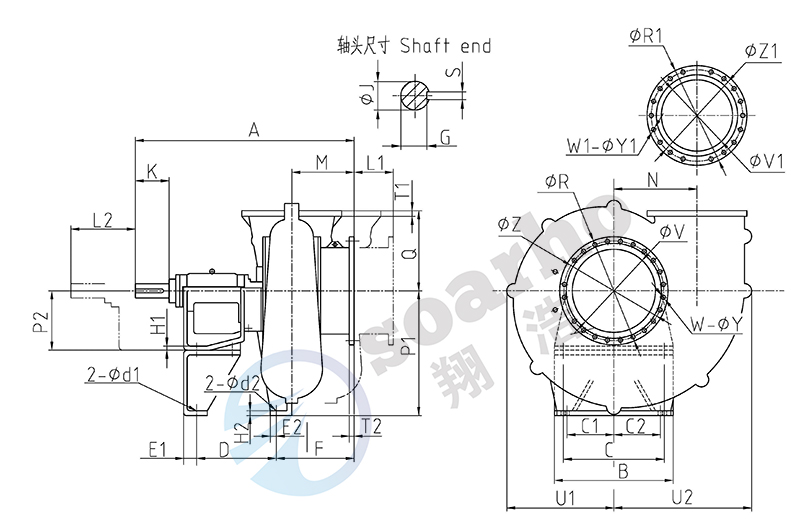

• Outline Drawing

| Type | Installation diameter | Shaft diameter | |||||||||||||||||

| A | B** | C1 | C2 | C | D | E1 | E2 | F* | H1 | H2 | M* | N | G | J | K | L1 | L2 | S | |

| 350X-TL(R) | 1450 | 660/1040 | 390 | 490 | 560 | 589 | 90 | 30 | 340 | 25 | 30 | 340 | 430 | 76.00 75.80 | 85.03 85.01 | 218 | 160 | 360 | 22 |

| 500X-TL(R) | 1773 | 1000/960 | 425 | 425 | 850 | 652 | 110 | 50 | 595 | 35 | 40 | 421 | 580 | 109.03 108.81 | 120.03 120.01 | 210 | 150 | 400 | 32 |

| 600X-TL(R) | 1855 | 960 | 425 | 425 | 850 | 670 | 110 | 50 | 667 | 35 | 40 | 525 | 700 | 109.03 108.81 | 120.03 120.01 | 284 | 330 | 610 | 32 |

| 700X-TL(R) | 2315 | 1300 | 550 | 730 | 1100 | 895 | 130 | 75 | 768 | 40 | 45 | 583 | 780 | 138.00 137.70 | 150.03 150.01 | 355 | 375 | 720 | 36 |

| 800X-TL(R) | 2460 | 1300 | 550 | 550 | 1100 | 885 | 135 | 75 | 933 | 40 | 45 | 712 | 930 | 138.00 137.70 | 150.03 150.01 | 355 | 550 | 800 | 36 |

| 900X-TL(R) | 2516 | 1350 | 575 | 575 | 1100 | 900 | 130 | 75 | 960 | 40 | 45 | 760 | 1075 | 185.00 184.70 | 200.04 200.01 | 365 | 550 | 900 | 45 |

| 1000X-TL(R) | 2870 | 1330/1975 | 888 | 888 | 1100 | 860 | 130 | 130 | 1366 | 40 | 80 | 1016 | 940 | 138.00 137.70 | 150.03 150.01 | 355 |

| 870 | 36 |

| Type | Installation diameter | Suction flange | Discharge flange | Anchor | Weight (kg) | |||||||||||||||

| P1 | P2 | Q* | T1* | T2* | U1 | U2 | R | V | W | Y | Z | R1 | V1 | W1 | Y1 | Z1 | d1 | d2 | ||

| 350X-TL(R) | 700 | 400 | 505 | 50 | 38 | 559 | 728 | 580 | 400 | 16 | 30 | 525 | 580 | 350 | 14 | 30 | 525 | 28 | 28 | 1858 |

| 500X-TL(R) | 950 | 500 | 665 | 60 | 44 | 735 | 946 | 715 | 500 | 20 | 33 | 650 | 715 | 500 | 18 | 33 | 650 | 42 | 40 | 4000 |

| 600X-TL(R) | 1050 | 500 | 775 | 48 | 40 | 901 | 1155 | 910 | 600 | 24 | 30 | 840 | 840 | 600 | 18 | 36 | 770 | 39 | 39 | 4575 |

| 700X-TL(R) | 1290 | 700 | 930 | 68 | 60 | 1080 | 1350 | 1025 | 768 | 24 | 40 | 950 | 1025 | 700 | 22 | 40 | 950 | 51 | 51 | 7280 |

| 800X-TL(R) | 1400 | 700 | 985 | 62 | 62 | 1141 | 1493 | 1125 | 900 | 28 | 40 | 1050 | 1125 | 800 | 26 | 40 | 1050 | 51 | 51 | 8300 |

| 900X-TL(R) | 1620 | 700 | 1050 | 70 | 70 | 1410 | 1765 | 1375 | 1000 | 28 | 51 | 1250 | 1330 | 900 | 26 | 39 | 1210 | 51 | 51 | 10720 |

| 1000X-TL(R) | 1400 | 700 | 1000 | 50 | 56 | 1153 | 1586 | 1455 | 1200 | 32 | 39 | 1330 | 1230 | 1000 | 28 | 36 | 1160 | 51 | 42 | 10800 |

NOTE: [*[Dimension including rubber gasket; [**":Support/Frame.

Product Categories : Horizontal Centrifugal Slurry Pump > TL(R) Series Desulfurization Pump (FGD Pump)